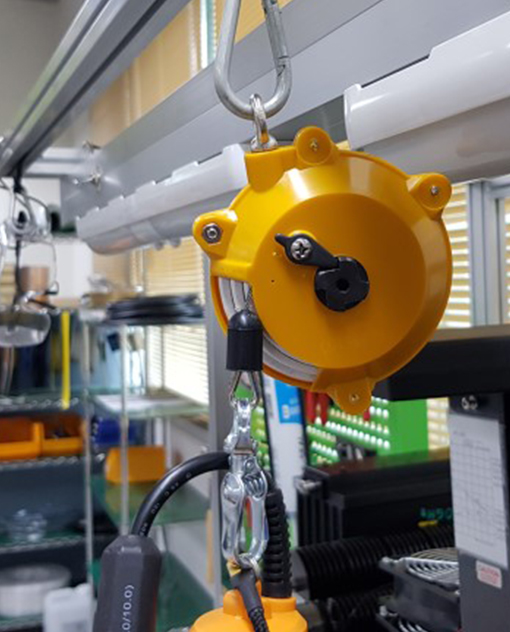

Spring Balancer and Its Application in Various Industries

In general, engineering and automobile industries widely use Spring Balancer . The tools like spring balancers, load balancers, and tool balancers are all designed to relieve the operator's responsibility of the heavy tools. With the least amount of effort, you can bring the tool down with slight strain or fatigue. Spring Balancers / Load Balancers / Tool Balancers' mechanisms counteract the load and pressure necessary for operation, making tool handling relatively straightforward. Most importantly, gravitational forces do not affect this action.

Simple, durable closed-body construction distinguishes Spring Balancer Manufacturer . They ensure fast connections and disconnections. Experienced manufacturers design Spring Balancers with highest standards. We also ensure the safety of the product and people working around the equipment.

What is the purpose of a spring balancer?

A Spring Balancer Manufacturer offers suitable products for small, medium, or significant lifting activity. Due to their flexible nature, various businesses across the world use it. Spring balancer works similarly to retractors and increases the retracting force when you increase the cable extension. When the working load is not in use it automatically retracts to its original position.

You may expect to see equipment hung from this product, keeping your workspace uncluttered, safer, and cleaner even while switching projects.

That implies that a continual downward force must maintain the suspended object's stretched posture. Upon releasing, the rewind spring's torque output increases when you extend the cable, retracting the hung object to the uppermost adjusted position.

Spring Balancer features :

● Closed body and cover: Prevents access of fingers into the assembly, preventing industrial accidents.

● Body Liner: To protect the body from wire rope wear increases the balancer's lifespan.

● Spring tension adjustment on the vertical axis will make modifying the spring tension from the ground level easier.

● Containerised spring assembly: Spring maintenance and replacement are made easier with concealed containers. .

● Wire Rope Replacement without Disassembly: A slot on the balancer allows for wire rope removal and insertion without disassembling the balancer. The long-range balancer does not have this capability. .

● Manufacturers make use of pressure die to design the parts, resulting in a consistent surface polish and complete interchangeability of spares. This enables large batch production, resulting in a shorter delivery time. .

● Safety Lock pin: In a spring failure, the lock pin locks the drum pulley, preventing the costly equipment from falling and injuring the operator. .

● Forge the top hook and allow the balancer to rotate 360 degrees.

Benefits of using a spring balancer in your industry :

There are a lot of benefits when you use a spring balancer in your industry, and you can think about these points before buying to see if it's the perfect product for you.

Here are the various benefits you can gain from using this product for your consideration. However, based on your specific business situation and requirements, you may always contact a member of the Spring Balancer Manufacturer in India to discuss a custom solution for your company.

1. They are appropriately positioned and balanced. The 360-degree hook puts you in the best possible working position. The spring balancer is simple to maintain, and the steel drum axle ensures a long service life. The kink-resistant steel rope reduces drum wear and does not require additional lubrication.

2. You may easily and quickly adjust the spring tension. There's a built-in shock absorber, as well as an adjustable rope that lets you stop the retraction at any point. Hence, overworking of the rope drum is avoided. Moreover, your version should come with a nylon rope guide to avoid wear and tear.

3. You can exchange individual components quickly due to the body's small form and the spring assembly's simplicity.

4. For the attachment of secondary safety chains, you get upper and lower suspension eyes. While using the spring balancer, you, your staff, and your operators will be safer.

5. Forged hooks with safety latches prevent the spring balancer and the suspended tool from being accidentally unhooked, ensuring that it stays in place when you or the operator is using it.

6. The automated drum-locking device locks the drum and secures the load even in a spring failure.

7. By employing a spring balancer, you will be able to do work at production and assembly stations more efficiently, allowing you to save time and complete previous jobs more quickly.

We hope this article has given you enough knowledge about spring balancers and understanding the benefits of employing the product and the value it can add to your business.

Are you looking for a reliable Spring Balancer Manufacturers In Mumbai

Get in touch with us!