Spring Balancer

"Discover the Efficiency of Spring Balancers | Quality Tools for Every Industry"

Spring Balancer

Spring Balancer

Spring Balancer

| Technical Specifications | |||||

|---|---|---|---|---|---|

| Model No | Capacity (kgs) | Cable travel (mtrs.) | Diameter of Cable (@ mm) | Mass (kgs) | |

| HSB-2 | 0.5 - 2.0 | 1.0 | 3.0 | 1.0 | |

| HSB-3 | 1.0 - 3.0 | 1.3 | 3.0 | 1.4 | |

| HSB-5 | 2.5 - 5.0 | 1.3 | 3.0 | 1.5 | |

| HSB-7 | 4 - 7. | 1.3 | 3.0 | 1.6 | |

| HSB-9 | 4.5 - 9.0 | 1. | 4.0 | 3.4 | |

| HSB-15 | 9.0 - 15.0 | 1.3 | 4.0 | 3.8 | |

| HSB-22 | 15.0 - 22.0 | 1.5 | 5.0 | 8.0 | |

| HSB-30 | 22.0 - 30.0 | 1.5 | 5.0 | 8.0 | |

| HSB-45 | 30.0 - 45.0 | 1.5 | 5.0 | 11.0 | |

| HSB-60 | 45.0 - 60.0 | 1.5 | 5.0 | 12.0 | |

| HSB-75 | 60.0 - 75.0 | 1.5 | 5.0 | 12.0 | |

| HSB-90 | 70.0 - 90.0 | 1.5 | 8.0 | 23.0 | |

| HSB-110 | 90.0 - 110.0 | 1.5 | 8.0 | 26.0 | |

| HSB-140 | 110.0 - 140.0 | 1.5 | 8.0 | 27.0 | |

| HSB-170 | 140.0 - 170.0 | 1.5 | 8.0 | 29.0 | |

| HSB-200 | 170.0 - 200.0 | 1.5 | 8.0 | 30.0 | |

| HSB-220 | 200.0 - 220.0 | 1.5 | 8.0 | 33.0 | |

Discover the Benefits of Using a Spring Balancer Tool in Your Workshop

How does a spring balancer work?

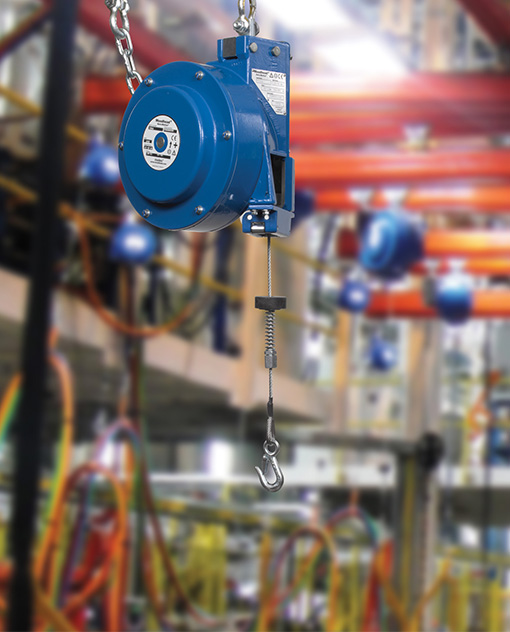

A spring balancer operates on the principle of balancing the weight of a load using a coiled spring. The tool consists of a spring mechanism enclosed in a housing, with a cable or wire attached to one end of the spring and a hook or clamp on the other end. The load is attached to the hook or clamp, and when the user pulls down or lifts the load, the spring extends or retracts accordingly.

The spring's tension can be adjusted to match the weight of the load, ensuring a perfect balance. The user can position the load at any desired height and let go, allowing the spring balancer to hold the load in place effortlessly. This mechanism not only reduces the physical effort required to lift heavy objects but also eliminates the need for manual support, freeing up the user's hands to perform other tasks.

Spring balancers come in various weight capacities, allowing you to choose the right tool for your specific needs. They can handle loads ranging from a few ounces to hundreds of pounds, making them suitable for a wide range of applications in workshops, factories, and other industrial settings.

Increased safety and reduced fatigue

One of the primary benefits of using a spring balancer in your workshop is the increased safety it provides. Lifting heavy objects manually can pose a significant risk of injury, especially when the load needs to be held for an extended period. With a spring balancer, the load is held securely, eliminating the risk of it slipping or falling unexpectedly. This reduces the chances of accidents and injuries, creating a safer working environment for you and your team.

Additionally, a spring balancer reduces worker fatigue. Lifting heavy objects repeatedly can be physically demanding and exhausting. It can lead to strain on muscles and joints, causing discomfort and increasing the risk of long-term injuries. By using a spring balancer, the physical effort required to lift and hold the load is significantly reduced, minimizing strain on the body and allowing workers to perform their tasks more comfortably and efficiently.

Increased Efficiency and Productivity

When working in a workshop, time is of the essence. Every minute spent struggling to lift heavy objects or transferring tools can eat away at your productivity. However, with a spring balancer, you can significantly reduce the time and effort required for these tasks. By providing a counterbalance, the spring balancer takes the weight off your hands, allowing you to effortlessly move objects and tools with minimal effort.

Not only does this save you time and energy, but it also reduces worker fatigue. Fatigue can lead to decreased focus and increased risk of accidents. With a spring balancer, workers can avoid the strain and exhaustion that often comes with manual lifting, leading to improved concentration and overall job performance. This increased efficiency translates to higher productivity, allowing you to complete tasks faster and take on more projects.

Moreover, the versatility of spring balancers is another factor that contributes to increased productivity. These tools come in various sizes and weight capacities, making them suitable for a wide range of applications. Whether you're working in a small workshop or a large-scale manufacturing facility, there's a spring balancer that can meet your specific needs. This adaptability ensures that you can efficiently handle different types of loads, maximizing your productivity and workflow.

Improved productivity and efficiency

Improved productivity and efficiency

Versatility and adaptability for various tasks

One of the standout features of a spring balancer is its versatility. These tools can be used for a wide variety of tasks in different workshop settings. Whether you need to lift heavy machinery, tools, or even delicate components, a spring balancer can handle the job.

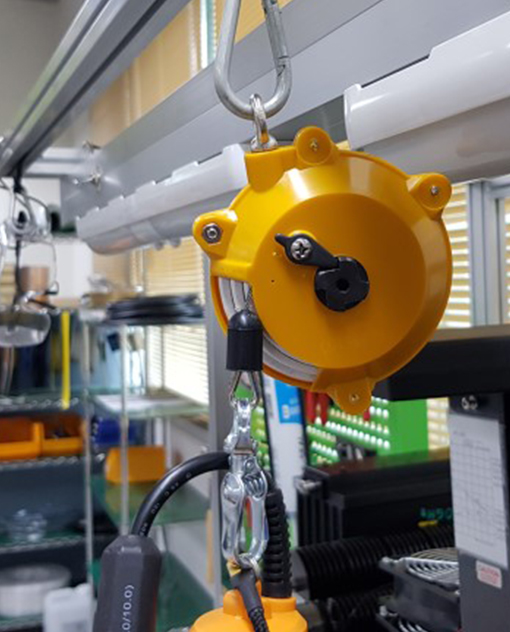

Spring balancers are commonly used in automotive repair shops, manufacturing plants, and construction sites. They are ideal for tasks such as lifting and positioning heavy engines, suspending power tools, or supporting welding equipment. The ability to adjust the tension of the spring allows for precise control over the load, making it suitable for delicate operations as well.

Furthermore, spring balancers can be easily integrated into existing systems or workflows. They can be mounted on walls, ceilings, or overhead structures, providing flexible solutions for various workstations. This adaptability ensures that a spring balancer can fit seamlessly into your workshop environment, regardless of its layout or requirements.

Cost savings and long-term investment

While the initial cost of purchasing a spring balancer may seem higher than traditional lifting equipment, the long-term benefits outweigh the investment. By reducing the physical strain on workers, a spring balancer helps prevent injuries and associated medical costs. It also minimizes the risk of damage to equipment or materials due to accidents or mishandling.

Moreover, the improved productivity and efficiency brought about by using a spring balancer can lead to cost savings. Projects can be completed faster, reducing labor costs and increasing overall profitability. The ability to optimize workflow and maximize resources allows you to take on more projects without compromising quality or timelines. In the long run, a spring balancer proves to be a valuable investment that pays for itself many times over.

Factors to consider when choosing a spring balancer

When selecting a spring balancer for your workshop, there are a few key factors to consider. First and foremost, you need to determine the weight capacity required for your specific applications. Ensure that the spring balancer you choose can handle the maximum weight of the loads you typically work with.

Next, consider the working range of the spring balancer. This refers to the vertical distance over which the tool can effectively balance a load. Depending on your workshop's layout and the tasks you perform, you may need a spring balancer with a longer or shorter working range.

Additionally, evaluate the quality and durability of the spring balancer. Look for well-established brands known for their reliable and robust products. A high-quality spring balancer will last longer and withstand the demands of daily use in a workshop environment.

Finally, consider any specific features or accessories that may enhance the functionality of the spring balancer. For example, some models come with adjustable cable lengths, quick-release mechanisms, or additional safety features. Assess your needs and choose a spring balancer that offers the features that will benefit you the most.

Maintenance and care for spring balancer tools

To ensure the longevity and optimal performance of your spring balancer, it is essential to follow proper maintenance and care procedures. Regularly inspect the tool for any signs of wear, damage, or loose parts. If any issues are detected, have them addressed immediately to prevent further damage or accidents.

Clean the spring balancer regularly to remove dust, debris, or grease that may accumulate over time. Use a soft cloth or brush to wipe down the tool and ensure that all moving parts are free from dirt or obstructions. Lubricate the spring mechanism as specified by the manufacturer to maintain smooth operation.

Store the spring balancer in a clean and dry environment when not in use. Avoid exposing it to extreme temperatures or humidity, as this can affect the tool's performance and lifespan. By following these simple maintenance practices, you can prolong the life of your spring balancer and ensure its reliability whenever you need it.

Discover precision and durability with our spring balancers Perfect for effortless load handling. Explore now

A spring balancer is a mechanical tool that holds and supports a suspended load. It uses a spring motor and a tapered or cylindrical drum to provide constant tension on the cable

Enhance productivity with our premium spring balancers. Our mechanical tools effortlessly support suspended loads, providing constant tension on cables. Whether you need load balancing, weightless equipment, or fatigue-free operation, we've got you covered. Explore our range today."

Spring balancers, also known as load balancers or tool balancers, are an ergonomic approach to negate the tool or equipment weight, thus minimizing the burden of the operator performing a tedious task in the industry or production environment. Long Stroke Spring Balancers Exporter in Mumbai offers products that are made for applications with high ceilings. They provide accurate "zero gravity" tool gripping that is free of drift and strain. The cable travels smoothly throughout the stroke thanks to the tapered drums and high-quality springs and bearings.

Spring balancers are designed to:

Suspend machines and equipment

Make tools and equipment seem virtually "weightless"

Allow tools to be pulled down with little pressure, without strain or fatigue

Free the operator from the weight of hand tools

When buying a spring balancer, you can consider things like:

Research and reputation

Quality standards and certifications

Range of products

Customization options

Technological expertise

Customer support

Weight capacity